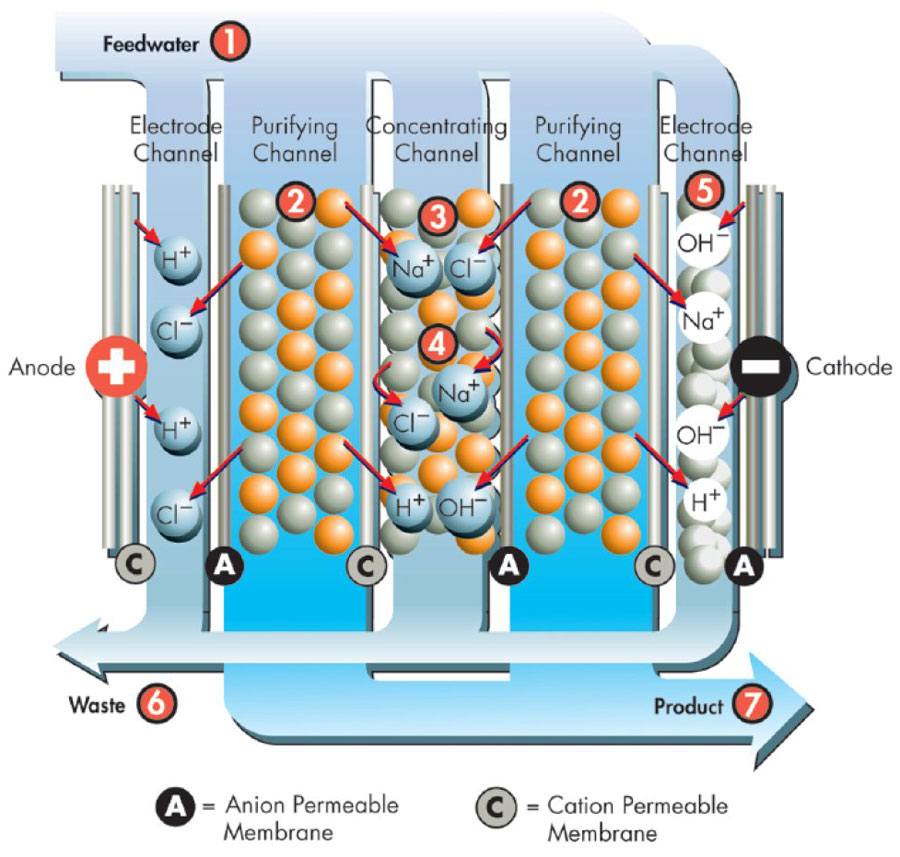

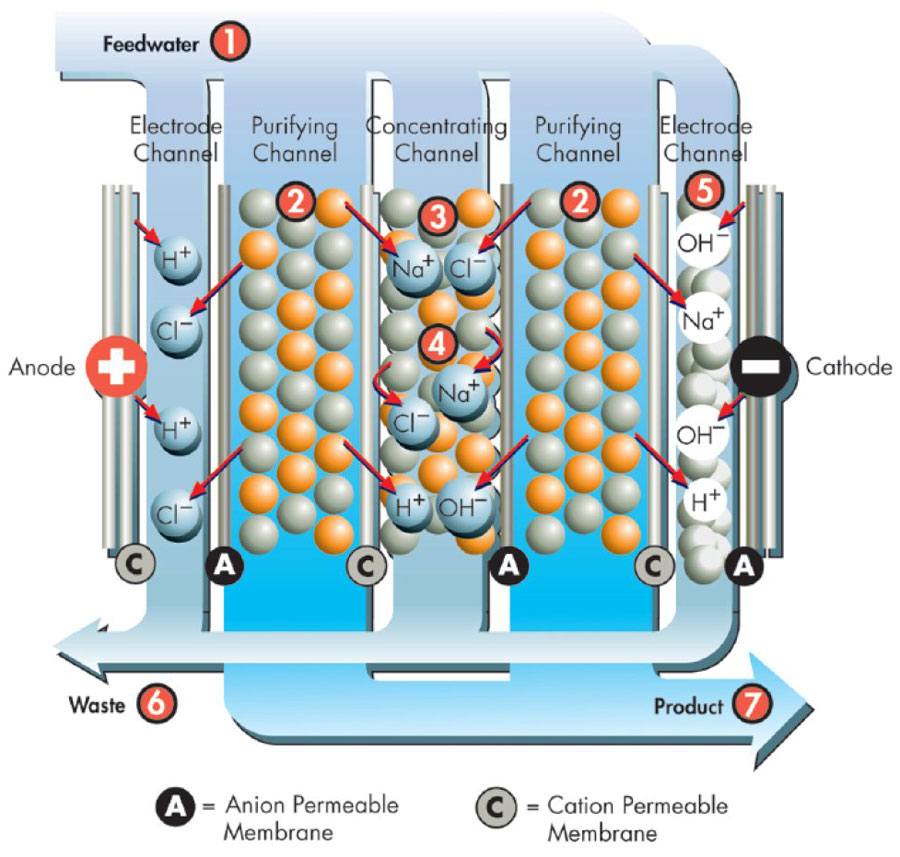

Electrodeionization (EDI)

Electrodionization is a water treatment technology that utilizes an electrode to ionize water molecules and separate dissolved ions (impurities) from water. It differs from other water purification technologies in that it is done without the use of chemical treatments and is usually a tertiary treatment to reverse osmosis (RO). There is also EDI units that use a small bed with ion-exchange resin to enhance the deionization further, this is often referred to as Continuous electrodionization (CEDI) since the electric current regenerates the resin mass continuously. CEDI technique can achieve very high purity, with conductivity being below 0.1uS/cm.

Advantages of EDI

Advantages of the EDI as opposed to the conventional systems of ion exchange resin are:

● Produce high quality of ultra pure water up to 16.0 MΩ.cm in constant flow.

● Chemical-free (used electricity instead of chemical for regeneration) and environmentally safe

● Simple and continuous production instead of batch cycle,

● Cost effective operation and maintenance,

● Non pollution, safety and reliablility,

● Required small footprint for operation.

● No neutralization system needed.

When to Consider Using EDI

EDI may be considered to be a competitive alternate process to:

Regenerable Mixed Bed Deionization

No acid or caustic bulk storage, pumping, waste neutralization or disposal issues. Lower operating cost due lower manpower requirements as well as the lack of chemical regeneration. Smaller footprint.

Service Mixed Bed Deionization (off-site regenerated rental vessels)

No ionic breakthrough resulting in a constant high quality of water. No rental vessels, associated freight or monthly demurrage charges.

Second pass of RO

Eliminates the need for a second bank of RO membranes and associated plumbing, pumping and control equipment.

Perceived Limitations of EDI

● Leaks: Leaks have been completely eliminated in some modern module designs.

● Sensitivity to chlorine: EDI is just as sensitive to the chlorine as thin-film reverse osmosis (RO) processes. This is easily addressed with proper pretreatment system design.

● Sensitivity to hardness: Most EDI devices have a 1 ppm hardness limit which is easily addressed with proper pretreatment system design.

● Not suitable for high CO2 loads: No ion exchange process is cost-effective for removal of large amounts of CO2. There are several effective and relatively inexpensive ways to remove CO2 in the pretreatment system.