Reverse Osmosis

Reverse osmosis (RO)

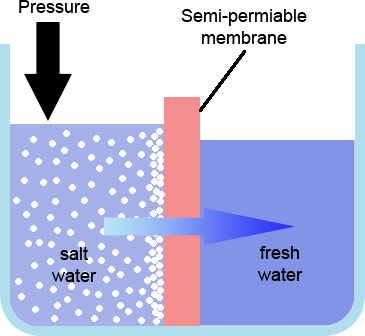

Reverse osmosis (RO) is a water purification technology that uses a semipermeable membrane under pressure to separate relatively pure water (or other solvent) from a less pure solution. This membrane technology is not properly a filtration method. In reverse osmosis, an applied pressure is used to overcome osmotic pressure, a colligative property, that is driven by chemical potential, a thermodynamic parameter. Reverse osmosis can remove many types of molecules and ions from solutions, and is used in both industrial processes and the production of potable water. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side. To be "selective", this membrane should not allow large molecules or ions through the pores (holes), but should allow smaller components of the solution (such as the solvent) to pass freely.

Because RO operates at a comparatively low temperature and is relatively energy efficient, it is employed in various applications, e.g., desalination, treatment of waste water, reclamation of minerals, concentration of whey and other food products, and purification of water (5,6). In recent years, RO has been used increasingly in making processed water for dialysis in hospitals and for certain cosmetics and drugs by pharmaceutical manufacturers (7,8). In addition to these applications, RO is capable of producing water of sufficient purity to be used as Water For Injection (WFI) and for the preparation of parenteral solutions

Technical Requirements of a RO System

● Feed water should be adjusted to proper pH and be prefiltered. The amount of TDS and suspended materials in the feed water after prefiltration should be controlled within the designed limits.

● Feed water and product water should be monitored for microbiological quality. The system should be disinfected when microbiological quality levels are exceeded.● All system components should be mechanically cleaned before disinfecting. Appropriate tests should be performed to assure that chemicals used in disinfection are completely removed from the system.

● The use of filters or ion-exchangers down stream of RO modules should be avoided.

● The RO system should be designed for continuous flow without traps, dead ends and pipe sections which may collect stagnant water.

● The chemical and microbial quality of water should be tested at predetermined intervals during a production cycle. In-line conductivity probes should be installed at key points for continuous monitoring of water quality.

● The equipment should be qualified and the RO system should be validated periodically, as well as operated and maintained according to manufacturer's instructions so that it can consistently produce water with acceptable quality.